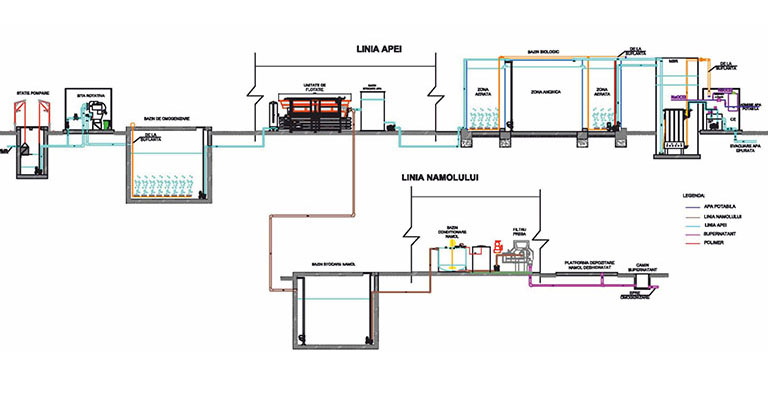

The general wastewater treatment stream comprises the following treatment steps:

- Mechanical step – through screening with a high-capacity small filter used for solid-liquid separation;

- Physical-chemical stage – in dissolved air flotation units. Dissolved air flotation is a process used to separate solid particles (suspended solids), liquids (oils and fats) and to separate and concentrate sludge. When the flotation process is preceded by a coagulation-flocculation treatment, the yield in the separation of solids in the suspension is much higher, with no problem at a true yield of 95%, thus providing a reduction of CB05 Of at least 40%, depending on the type of waste water;

- Biological step achieves organic matter reduction, nitrification, denitrification and biological reduction of phosphorus in active sludge ponds;

- Final disinfection – The stage of final disinfection of the purified water before its discharge into the emissary is done by chlorination using chlorine dispensing pumps, ultraviolet sterilization or membrane ultrafiltration;

- The sludge processing step – the sludge from the wastewater treatment process is subjected to processing processes, depending on the requirements of the beneficiary and the rules imposed by the legal regulations in force.